- +91-7972517591

- solution@plutotools.com

08:30-16:00 Monday-Thusday 08:30-15:30 Friday excludeing public holidays

08:30-16:00 Monday-Thusday 08:30-15:30 Friday excludeing public holidays

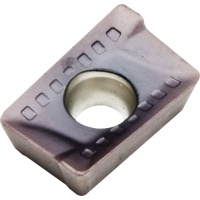

APKT 1003 PDR UM25 Carbide Inserts for Milling PVD Coated Grade UM25 (M25, P35, K35 with Multi Layer NacO3 PVD Coating) for all types of Steel, Stainless and conditionally Hi-temp Alloys and Cast Iron

Dimensions for APKT 1003 PDR UM25 (mm)

| Cutting Edge Length | Inscribed Circle or Width | Thickness | Hole Dia | Corner Radius | Side Clearance |

| 11.09 | 6.66 | 3.5 | 2.8 | 0.4 | 11° |

General Cutting parameters

| Material | Hardness HB | Cutting Speed VC: m/min | Depth of Cut ap(mm) | Feed f(mm) | Application Choice |

| Non alloyed steel 0-0.45% C | 150-250 | 70-170 | 1.0-6.0 | 0.08-0.15 | Good |

| Low alloyed steel | 250-300 | 70-170 | 1.0-6.0 | 0.08-0.15 | Good |

| High alloyed steel | 200 | 70-170 | 1.0-6.0 | 0.08-0.15 | Good |

| Corrosion resistant steel | 200 | 70-170 | 1.0-6.0 | 0.08-0.15 | Good |

| Stainless - Ferritic | 200 | 70-130 | 1.0-3.0 | 0.08-0.13 | Good |

| Stainless - Austenitic | 180 | 70-130 | 1.0-3.0 | 0.08-0.13 | Good |

| Stainless - Duplex | 230-260 | 70-130 | 1.0-3.0 | 0.08-0.13 | Good |

| Stainless - Martensitic | 330 | 70-130 | 1.0-3.0 | 0.08-0.13 | Good |

| Grey cast iron | 180 | 70-170 | 1.0-6.0 | 0.08-0.15 | OK |

| Spheroidal cast iron | 160 | 70-170 | 1.0-6.0 | 0.08-0.15 | OK |

| Malleable / Tempered iron | 130 | 70-170 | 1.0-6.0 | 0.08-0.15 | OK |